Free Trial

Accurate and Reliable 3D Scanning of Parts

Modernize Your Design and Manufacturing Process with Our State-of-the-art 3D Scanning Services!

Are traditional prototypes and end-of-life components slowing down your manufacturing process? Replace real-life references with digitized files by tapping into the power of 3D scanning of parts services.

At MOS, we specialize in providing non-destructive and comprehensive 3D scanning of parts services. We push past the barriers of physical parts by leveraging advanced scanning technologies to create sophisticated and customizable 3D scans of existing parts and assemblies. Whether you are looking to reverse engineer, inspect quality, or streamline the manufacturing process, our 3D scanning services ensure accurate, high-resolution models that meet your specific needs. Trust us to turn your physical components into digital assets for innovation, efficiency, and excellence through intelligent workflow automation.

Get Started Today!

Get in touch with us at 1-800-670-2809 for a custom scanning solution!

Benefits of 3D Scanning of Parts

Unmatched Accuracy

Enhanced Design Iterations

Preserve History

Restore Old Parts

Faster Prototype Creation

Boost Collaboration

3D Scanning Services Provided at MOS

Whether you are in the manufacturing, automotive, or aerospace industry, our teams of experts work closely with our clients to ensure the end product is a robust and refined digital version of physical parts. For scenarios where only 2D part drawings exist, we specialize in converting your blueprints into precise 3D models. Our 2D to 3D CAD conversion services transform detailed part drawings into accurate 3D representations, which can then be used for 3D scanning to create detailed digital replicas of your parts. Our services are tailored to meet your specific requirements for projects of any scale by leveraging AI-based workflow automation to optimize scanning processes and ensure consistent results.

We provide the following services:

Industries We Serve

Manufacturing

Automotive

Healthcare

Construction

Casting

Aerospace

Step into innovation and transform your physical data into digital perfection!

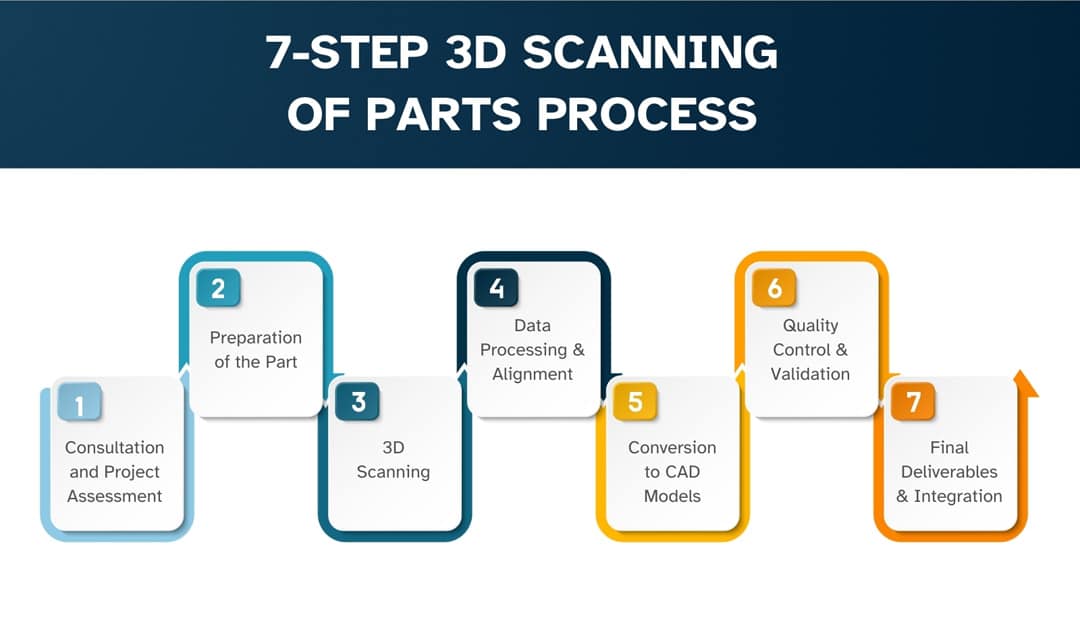

3D Scanning of Parts – What the Process Involves

Our team of 3D scanning experts follows a meticulous and systematic approach to convert 3D scanned data to 3D modeling, ensuring optimal accuracy and efficiency. Backed by extensive expertise and workflow automation tools, we capture every intricate detail of your parts. These highly detailed CAD models are ideal for design, reverse engineering, and other applications. Below is an overview of our end-to-end process, guaranteeing each part is accurately digitized and seamlessly integrated into your workflows:

What Makes Us the Right Choice?

Partnering with MOS allows you to optimize your manufacturing processes, minimize dependency on physical inventory, and streamline product development. Our key advantages include:

FAQs

Is 3D scanning safe for all parts?

Can 3D scanning be done remotely?

What are the benefits of using 3D scanning over traditional measurement methods?

What file formats does 3D scanning produce?

How long does 3D scanning of parts take?

Have further questions about our 3D Part Scanning Services?

Recent Posts

A Proactive Data Security System Can Ensure Better Business Productivity and Growth

As businesses navigate the era of digital transformation, securing data has become an absolute necessity. With sensitive...

The Role of Document Scanning in a Disaster Recovery Plan

Disaster in business comes in all forms – from cybersecurity threats to operational failures that disrupt a company’s workflow....

Best PDF to Word Converter Tools

The PDF format is one of the most widely used file types across various industries, including real estate, education, and...