Big data has immense potential in almost every industry, including the manufacturing sector. Organizations that collect and organize useful data can benefit from data analytics to answer various questions and improve functioning. One of the first steps towards these goals is digitization of paper documents. Leveraging document scanning services is a practical way to convert large volumes of physical files into electronic format.

Manufacturing companies have historically used physical assets and machinery to power their production processes. But these days, data is a crucial tool for businesses in all sectors. Businesses in the manufacturing sector, in particular, have begun to use data to their advantage by leveraging data analytics. Manufacturing organizations can obtain insights into their processes by analyzing large volumes of data. This makes it easier to find inefficiencies, take steps in improve processes, reduce costs, and enhance customer satisfaction.

Data Analytics Applications in Manufacturing

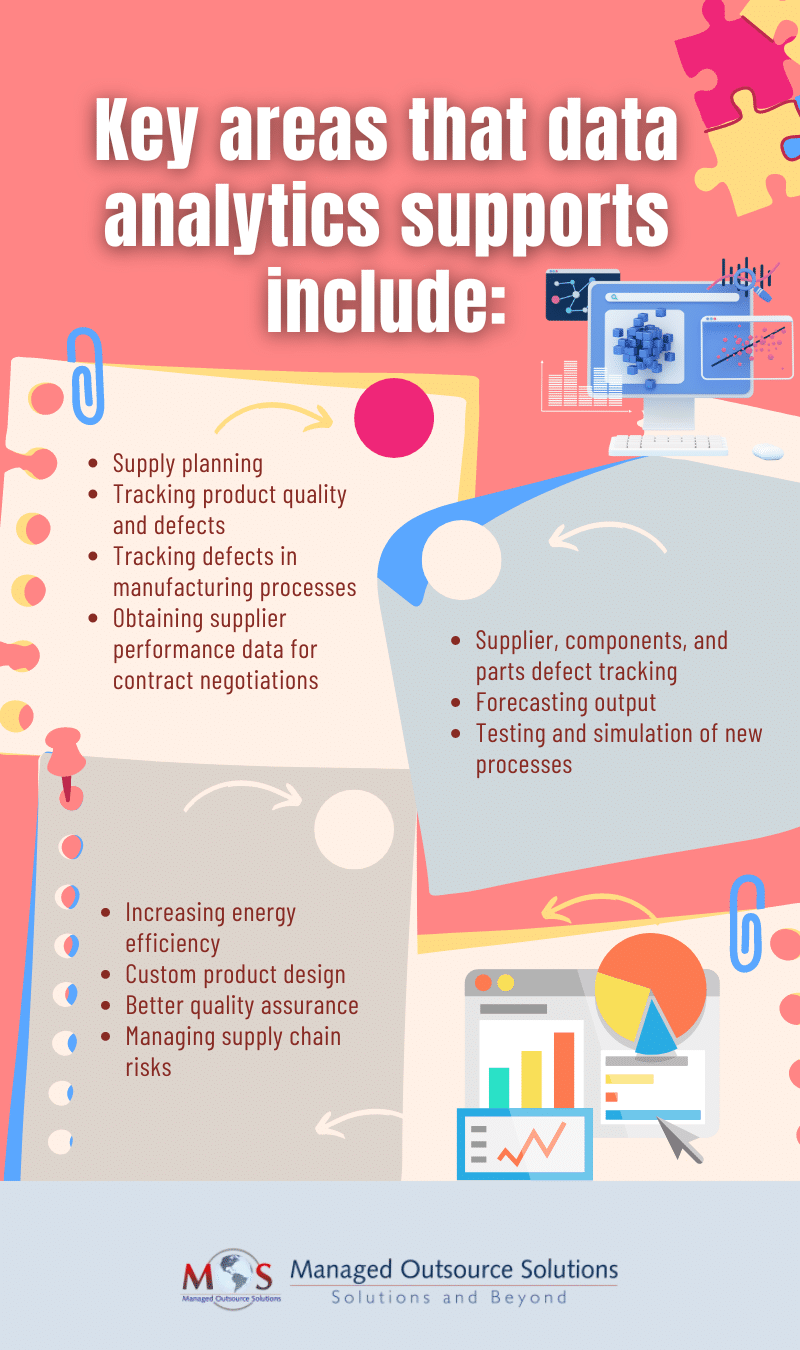

There are a plethora of ways the manufacturing industry can use data analytics. However, supply chain optimization, quality control, and predictive maintenance are the three most significant areas where analytics can enhance the manufacturing process.

- Predictive Maintenance: One key application of data analytics in manufacturing is predictive maintenance. Manufacturers can avoid production disruption and/or downtime by using data to undertake preventive maintenance before equipment or machine breakdowns occur. For instance, sensors are able to gather data on the performance of machines, and algorithms are able to spot abnormalities and patterns that indicate impending equipment problems in order to prescribe the best maintenance plans. Manufacturers can plan maintenance in advance of problems by using predictive maintenance, which has two key advantages:

- Cost Savings: Predictive maintenance has the potential to significantly lower the expenses related to equipment breakdowns and unscheduled downtime. Manufacturers can save costs associated with missed production, product defects resulting from equipment failures, emergency repairs, and other issues by minimizing failures and breakdowns.

- Reduction of unplanned downtime: Predictive maintenance also minimizes production schedule interruption, maximizes equipment uptime, and saves money and time that would otherwise be wasted due to unplanned downtime.

- Supply Chain Optimization: Data analytics enables manufacturers to streamline the production process, from sourcing raw materials to delivery of goods, driving optimal supply chain management. This is made possible through real-time collection, evaluation, and interpretation of data about supplier performance, inventory levels, and demand patterns. With this information, manufacturers can make well-informed decisions about how best to manage supplier relationships and optimize inventory management and order placement through demand forecasting. For manufacturers, supply chain optimization through data analytics provides two key advantages:

- Better inventory management: It provides real-time insights into consumer wants, market trends, and behavior. These elements help producers keep ideal stock levels at all times, which lowers the expenses related to having too much inventory.

- Demand forecasting: By providing precise demand forecasting, data analytics gives manufacturers a competitive edge. By improving their ability to forecast future demand, analytics allows manufacturers to consistently maintain the correct amounts of various products on hand.

- Quality Control: The aim of any manufacturing process is to maintain consistently high quality in goods produced, and data analytics can help with this by employing quality control software.

-

- Prediction: By anticipating possible flaws before they arise, predictive analytics can greatly improve quality control. Analytics models are able to recognize patterns that may point to possible faults by examining data from sensors, production logs, and other sources.

- Early intervention: Even in cases where analytics is unable to anticipate possible flaws, it can detect actual flaws as soon as feasible. This enables manufacturers to take proactive measures, such as intervening and making changes, to guarantee that non-defective items continue on the production line.

- Root cause analysis: Finding the source of a problem as soon as it arises is essential to preventing more problems. By looking at several variables and distinguishing between correlations and causes, data analytics can locate problems and determine their true cause. By tackling the underlying reason, manufacturers can improve the manufacturing process going forward in addition to solving acute problems.

In the present Extreme Data Economy, data has become more important than ever before. In 2011, the World Economic Forum recognized personal data as an asset for corporations. Angela Merkel, chancellor one of the world’s largest manufacturing economies, has said that data will be the raw material of the 21st century. Data provides an opportunity for social economic growth and helps you understand your customers, gain valuable insights and make better business decisions.

Effective Data Analytics and Use – Real Life Examples

A report from Modor Intelligence estimates that the big data analytics market in manufacturing will be valued at USD 9.07 billion in 2024 and expand at a compound annual growth rate (CAGR) of 16.24% to reach USD 19.25 billion by 2029. As data increases, it becomes more unpredictable and complex. Real time insights derived from data is important to become a true data-powered business.

In the manufacturing industry, the speed and efficiency of operations can be improved with data analytics. Analytics provides focused and actionable insights that are vital to continuously tweak the production line.

A Honeywell Process Solutions KRC Research study found that 67 percent of manufacturing executives invest in Big Data analytics in order to reduce cost. They also invest in data integration and management to gain a competitive edge. The study also found that big data analytics could reduce breakdowns by up to 26 percent and cut unscheduled downtime by nearly a quarter.

Tire manufacturer Continental revamped their business model to be known as a technology company first rather than premium tire manufacturer or an automotive supplier. Continental has built remote monitoring technology into their process to quickly collect data. This new technology has transformed fleet maintenance from a laborious process to an automated, proactive and targeted process. Their transition to a data-powered company helped them thrive and capitalize on extreme data in a way that makes business sense for them.

Toyota completed a reorganization focused on expanding data science technology. They developed a program called Toyota Connected by consolidating Toyota initiatives across data analytics, data center management and data driven services. It provided connected and autonomous cars to gauge the tastes and preferences of customers.

Toyota and Continental are examples of industries harnessing the power of data to revolutionize their business. These companies are getting ahead of the learning curve and overcoming the challenges and gradually transforming their data. With data increasing in importance and with the implementation of GDPR, the roles of chief data officers, data scientists and data protection officers have become even more significant. Data powered businesses operate at high speed and scale with higher complexities, driving a new era of extreme data management.

Advantages of Data Analytics

Big data analytics can help reduce processing flaws, increase efficiency, improve quality of the products, and save time as well as money.

An experienced data entry company can ensure clean and actionable data that can be analyzed to gather valuable insights. With accurate data and strong analysis and visualization tools, the manufacturing sector can obtain a more detailed understanding of how production line operate and how it can be further streamlined for business success.